We live in an unstable world, where a dangerous situation can arise anywhere, at any time. For your personnel to successfully defend themselves—and others—it’s vital that their skills remain razor-sharp.

Often, the only way to do that is with a modular training facility.

Unfortunately, these incredibly beneficial facilities have gotten a bad rap at times as being non-user specific, inflexible, and even poorly designed or built.

But that couldn’t be further from the truth.

As one of the world’s leading manufacturers of modular training facilities, CoverSix has created training solutions for the U.S. military, first responders around the globe, and many others which means we know these facilities like no one else.

So, to help those of you who may be new to the subject or are just trying to separate fact from fiction, this is a breakdown of the unique advantages of modular training facilities. We’ll also cover the different variations of training facilities available to you so you can start creating a facility that meets your specific needs.

Of all the misnomers surrounding modular training facilities, most seem to be related to what turns out to be their biggest strength—modular construction. So, to help clear things up, here are just five of the main benefits of utilizing modular construction.

First, it has been estimated that a modular building can cost up to 35 percent less than a traditional stick-built building. (But don’t confuse cost with quality, as you’ll see later, modular construction turns that whole paradigm on its head.)

Second, modular buildings can be constructed anywhere from 25 to 50 percent faster than their traditional counterparts.

How?

Nearly all of the construction related to a modular building is completed off-site, which means no delays due to inclement weather—and no delays mean increased efficiency.

Typically, when talking about safety at CoverSix, we’re touting our structures' unique protections: ballistic-resistance, blast resistance and forced entry resistance, but for this point, we’re going to talk about the safety advantages related to the actual construction process.

With approximately 80 percent of the construction process conducted off-site, fewer contractors are on-site for a shorter time. This reduction of boots on the ground means fewer opportunities for accidents to occur on-site and, as a bonus, fewer disruptions to your ongoing operation.

OK, so this is where things get interesting and where you’ll hopefully see that anyone disparaging the quality of modular construction doesn’t know what they’re talking about.

Let’s start with the frame.

While traditionally constructed buildings have a frame consisting of a network of two-by-fours, modular buildings boast a solid, all-steel ribcage that is stronger, more dependable, and longer-lasting than the competition.

Next, modular buildings are constructed in a controlled environment which virtually eliminates the variables that come with traditional construction. That means there’s never any “playing it by ear” to work around a potential problem. Instead, modular buildings are built to exacting standards that are repeated time and again.

But will you have to make sacrifices to its interior finish?

Nope.

There is virtually nothing that can be done in a traditional stick-built structure that can’t be done in a modular building. That means all of the amenities and modern comforts can be yours—the only thing holding you back is your imagination.

Unlike traditionally constructed buildings, modular buildings can be easily changed to meet your changing needs. If you need more room or want a different configuration, it’s as simple as bringing in (or taking away) additional units and organizing them as you see best.

To do that with a traditionally built facility could mean tearing it down and starting from scratch.

Looking to reorganize your site or need to move your facility to the other side of the world?

No problem.

Modular buildings are completely portable, which means you’ll never lose your investment, and your personnel will always have access to the facilities they need, no matter where they are.

Modular training facilities come in a wide variety of shapes and sizes to keep individuals safe, and their skills honed. Here is a quick rundown of the six most popular varieties.

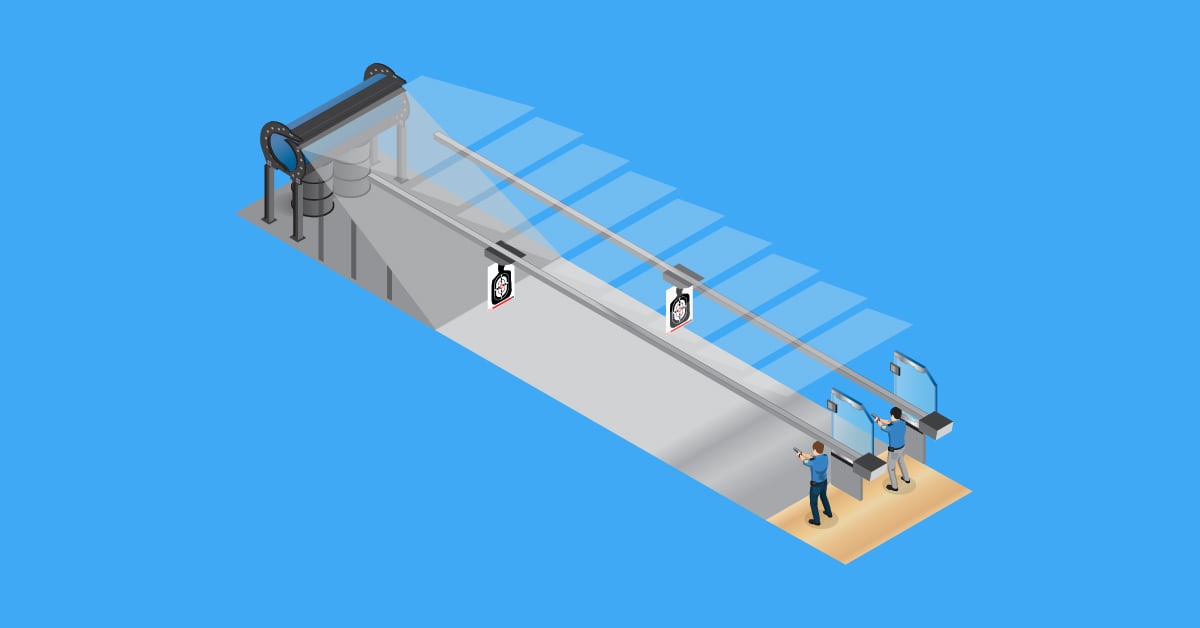

Offered in various lengths and lane configurations, a Modular Small Arms Range offers the safety and security of a traditional shooting range along with the flexibility and portability of modular construction.

These state-of-the-art facilities accommodate ammunition ranging from 9 mm up to .50 caliber, offer a wide range of targeting systems (overhead retrievable, pop-up, and running man), allow for movement during full-cover drills, and have adjustable lighting for day and night training scenarios.

These hardened modular facilities provide reliable shelter on active explosive ranges. While resistant to shrapnel, these facilities also offer the perfect viewpoint for monitoring training in real time.

Close-quarter combat facilities provide a live-fire environment perfect for everything like basic or advanced tactical weapons drills, room clearing exercises, building approaches, search drills, or explosive method-of-entry training.

CQCs allow personnel to train in real-world settings complete with customizable room layouts, stairs, lift shafts, and other internal features combined with reactive target systems and immersive visual and audio effects.

Military operations can take place in virtually every environment imaginable. MOUT units simulate a man-made environment that can be configured to represent just about anything, like a single-story building or even an entire city.

They are designed for a variety of training needs, like adaptive urban assault, building search, urban climbing, and simulated force-on-force training to name a few. Skills houses can do it all. These multi-faceted facilities combine realistic walls, doors, rooms, and hallways with custom configurations to create a realistic training environment critical to developing the confident and conditioned responses needed from soldiers and first responders.

There are control rooms, and then there are hardened control rooms. Designed to withstand repetitive blasts while protecting personnel and equipment, hardened control rooms offer all the features you would expect but with the added peace of mind that only comes with a ballistic-resistant structure.

When you decide that a modular training facility is right for you, the first step is to find a reputable manufacturer.

While you’ll want to find someone who offers the type of facility you’re looking for, it’s also important to take a good look at the company itself and its overall commitment to safety and quality.

A good benchmark for this is the company’s TRIR score. Handed out by the Occupational Safety and Health Administration (OSHA), a TRIR score evaluates the number of accidents that have occurred at an organization compared to the total man-hours worked.

Next, sit down with a representative from the manufacturer to go over the precise environment and all the potential threats your facility will face. This review will help determine whether you’ll need blast-, ballistic- or forced-entry resistance (or all three) factored into the design.

From there, be sure to stay involved with the design process all the way through construction so that you can have a hand in its layout, amenities, and finishing touches.

Head-to-head, modular training facilities are more cost-effective, safer, higher quality, scalable, and portable than their traditional, stick-built counterparts. Available in various configurations to meet virtually every training need, these facilities offer the added protection needed to keep personnel safe so they can focus on improving and maintaining their skills.

You can download our brochure on modular training facilities or contact a representative today to learn more about the modular training facilities available from CoverSix.